Achieve short lead time with three strengths

-

- In-house 3D drawing

- We accept 2D drawing from clients, and then converted to 3D data internally and checked for any flaws. Normally, this process is outsourced or checked in accurately, which increases the number of the time we have to communicate with customers and leads to delays in delivery. Koyo Foundry has a large number of experienced staff, which helps to shorten the delivery time through smooth communication.

-

- Self-manufacturing of foam model processing

- Two DNC machines are used to process Styrofoam foam models in-house. In-house processing of foam models means that we can confirm that the process has been taken into account at the drawing stage, so there is no waste in the confirmations steps to the customer. In addition, the speed with which we are able to process in one working day, including the adjustment of internal systems, support the realization of short delivery times.

-

- Possession of a large capacity cupola

- In casting process, a large volume of iron is melted at once so it is not possible to pour iron everyday. The amount of iron that can be melted at one time also determines the production capacity. Koyo Foundry has a large capacity cupola of 7.5t and maintains a monthly production capacity of 400t. Therefore, we are able to respond to customers’ urgent orders and achieve short delivery times through quick manufacturing.

PRODUCT LINEUP

-

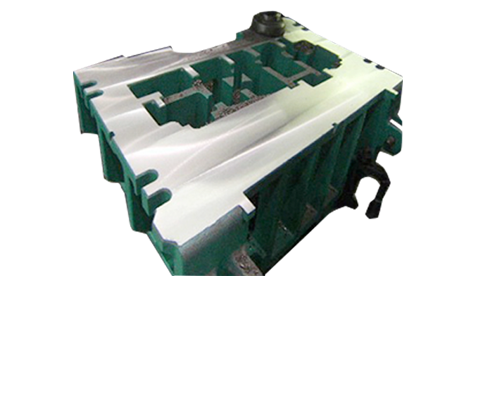

- Automotive molds

- Molds used in the manufacture of automobile parts must meet high standards of durability and precision. Koyo Foundry has been delivering our products to major automobile manufactures. We will respond to your requests based on our accumulated experience.

-

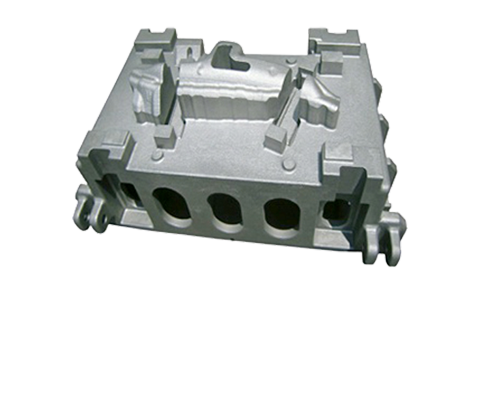

- General industrial parts

- This is the on-of-a-kind-parts required for industrial machines, and an area where high performance can be achieved by casting. Comparing to the other general methods, we provide the casting products with quick low cost in a short lead time.

-

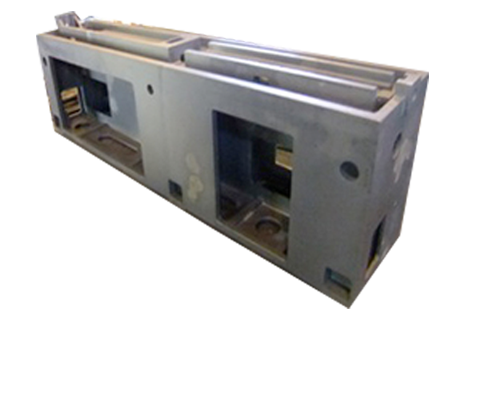

- Machine tool parts

- We specialize in manufacture of original parts in small lots of wide variety of products, and have delivered wide variety of products.

-

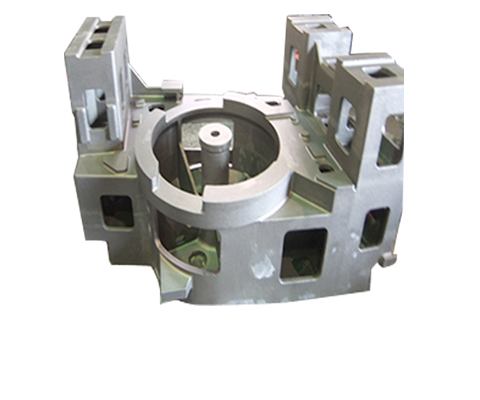

- Aluminum refining

- Aluminum smelting requires a shape that is specific to the site. Koyo Foundry has been working on many products for aluminum refining. We are confident what this know-how will lead to the reliability that our customers are looking for.

-

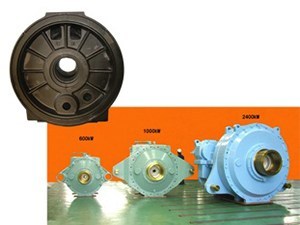

- Wind power generation

- The bearing covers that support the wind turbines blades are very heavily stressed. In addition, it must be able to withstand corrosion from the outside environment, and only casting can produce parts that meet these requirements. Koyo Foundry manufactures such parts by casting.

-

- Others

- We are taking on the challenge of new initiatives that will allow us to utilize our strengths in casting.

CORPORATE PROFILE

| Founded | February 1955 |

|---|---|

| Name | koyo casting CO.,Ltd |

| Head Office | Address:2624 Yononishide, Iga City, Mie 518-1152 |

| Area | 10,500㎡(Plant:3,740㎡ 、Office:274㎡) |

| Phone Number | (+81)595-39-0080 |

| FAX | (+81)595-39-0081 |

| Email Address | info@koyochuzo.co.jp |

| Capital | 48 million yen |

| Member of the Board Directors | Chairman Yutaka Shirae |

| CEO(Chief Executive Officer) Hajime Shirae | |

| Managing Director Mayumi Shirae | |

| Bank | Kansai Mirai Bank Imazato Branch |

| Japan Finance Corporation East Osaka Branch | |

| Hyakugo Bank | |

| Number of employees | 50 (43 men, 7 women) |

| Industry | Pig iron casting industry |